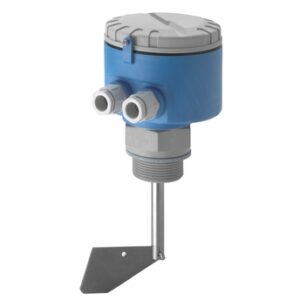

A level indicator is a device used to measure and monitor the level of a substance within a system or tank, silo, or hopper. It provides essential information on the amount of material present, which is crucial for process control, inventory management, and safety operations.